Wilson Sporting Goods partnered with EOS, a 3D-printing solutions company, to debut the first-of-its-kind 3D-printed airless basketball prototype.

Revealed during the first round of the AT&T Slam Dunk Contest last February 18th, NBA player KJ Martin tested out the airless basketball on the court to test its real-life functionality.

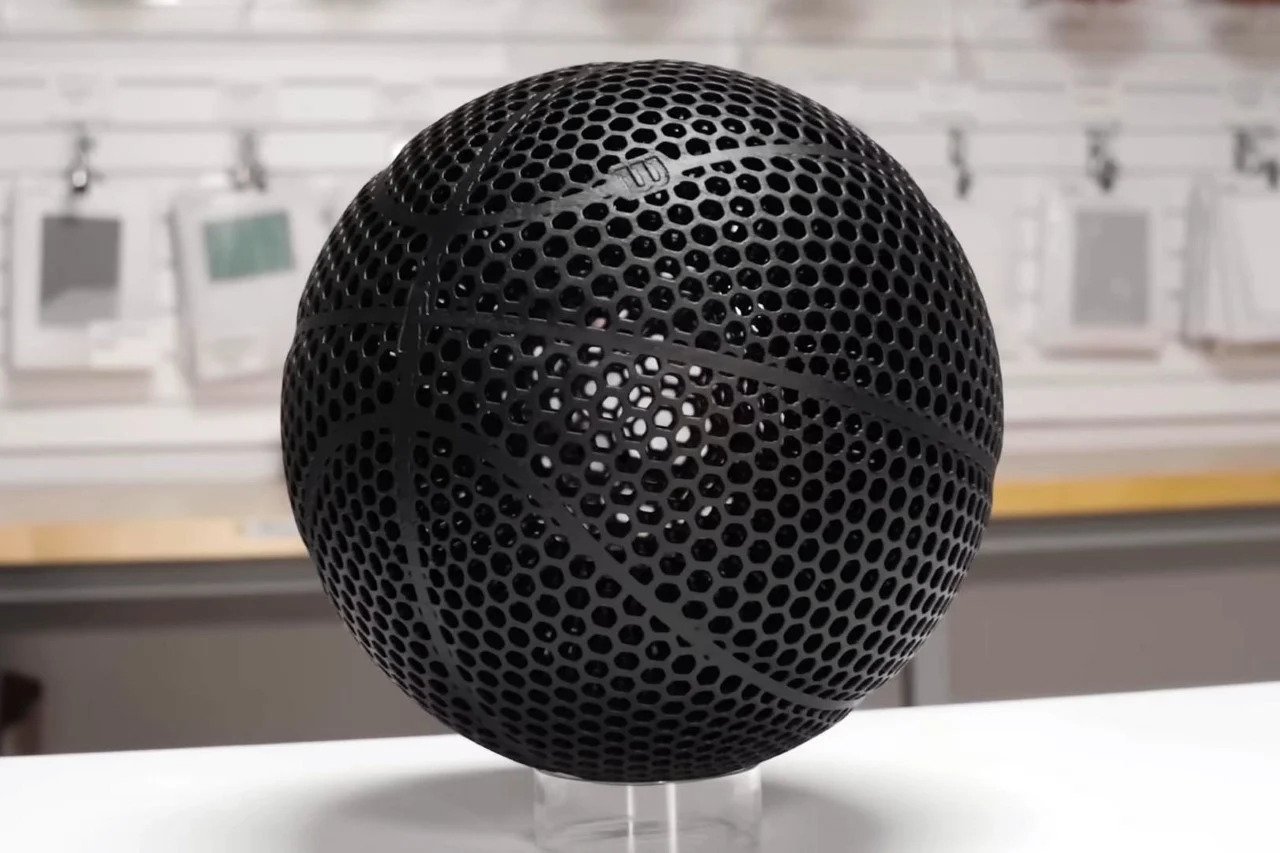

EOS used additive 3D printing technology to produce the 3D-printed airless basketball prototype, which features a revolutionary design that features hundreds of hexagonal structural holes instead of an inflatable air sac.

Designed by the team behind the official NBA game ball, the black-dyed 3D-printed ball made of research-grade materials closely matches the performance specifications of a regulation basketball, including its weight, size, and bounce. The porous surface, a series of small hexagonal lattice structures that allow outside air to pass through freely, also comes with the traditional eight-panel seam structure to give the ball its recognizable basketball look.

Though shown to be playable, the revolutionary ball design is still in its prototype stage and is far from replacing the regulation basketball. Rigorous testing is needed before it becomes a commercial reality, but it’s a future that may be just over the horizon.

Take a look at the Wilson 3D-printed airless basketball prototype here, and check out the Wilson website for more details.